ASI Torque 35 RC Medium Viscosity Retaining Compound Adhesive Systems, Inc.

$ 115,00 $ 46,00

About the ASI Torque 35 RC Medium Viscosity Retaining Compound

The Adhesive Systems Inc ASI Torque 35 RC is a medium viscosity retaining compound ideal for slip fitted parts. The 35 RC retaining compound fixtures in around 10 minutes and has a shear strength of up to 4,200 psi. The ASI Torque 35 RC also meets the MIL SPEC MIL-R-46082B, Type III meaning it can replace other more expensive name brands without sacrificing quality. ASI Torque 35 RC is an adhesive made in the USA.

ASI Torque 35 RC Specifications

- Color: Green

- Viscosity: 2,000 cps

- Gap Fill: .010″

- Shear Strength Steel/Steel: 4,200 psi

- Temperature Range: -60 to 350°F

- Cure Speed (Fixture/Full): 10 Minutes/8 Hours

- Specific Gravity: 1.05

Compare ASI Torque 35 RC to

-

LOCTITE™ 635

* The product names used in this website are for identification purposes only.

* All trademarks and registered trademarks are the property of their respective owners.

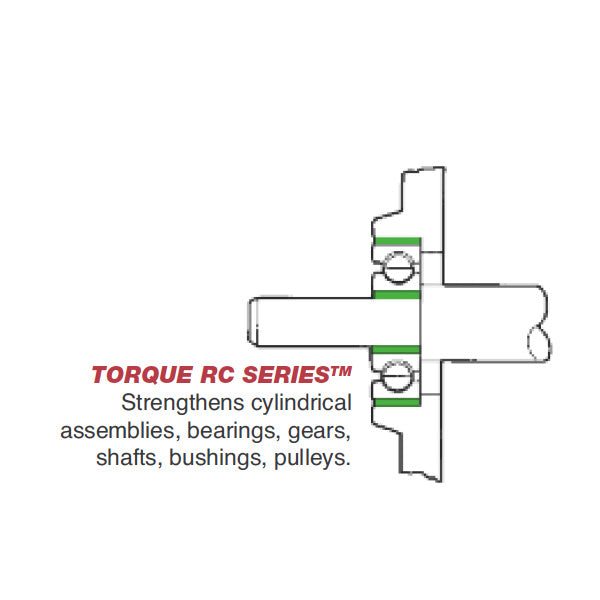

About the ASI TORQUE RC Series Retaining Compounds

The TORQUE RETAINING SERIES is engineered to greatly increase the shear strength of cylindrical, non threaded assemblies. These products fill the inner space and surface irregularities between the parts forming a tough, durable polymer, that creates a unitized, strong, precision assembly, preventing corrosion. They are single component, solvent free compounds that are ready to use right from the bottle, or can be easily automated. The TORQUE RETAINING SERIES is formulated in a wide range of viscosities, gap filling ability, cure times and strength characteristics. This technology greatly enhances the reliability and performance properties of the finished assembly. Even in the best press fit application there is only 20 to 30 percent actual metal contact between the surfaces.

The TORQUE RETAINING SERIES fills all the voids between the parts increasing the overall strength of the assembly by 2 to 3 times that of the original press fit. Other retaining and locking devices can be eliminated such as keyways, set screws, splines, tapers, knurls, etc. Machining tolerances can be relaxed lowering the cost of the assembly and simplifying the assembly process. Improved quality, reliability, cost effectiveness, ease of use, are just a few of the many benefits the TORQUE RETAINING SERIES brings to improve the manufacturing techniques in your assembly applications.

| Choose Size | 10 MIL Bottle – Quantity 10, 50 MIL Bottle – Quantity 10, 250 MIL Bottle – Quantity 2, 1 L Bottle – Quantity 4 |

|---|

Fast Shipping and Professional Packing

Our long-standing relationships with UPS FedEx DHL and other international carriers gives us the ability to provide an array of shipping services. Our warehouse staff are educated to pack your items exactly according to the specifications that we supply. Before they are shipped the goods are thoroughly inspected and secured. Every day we ship hundreds of packages to our customers from all over the world. This is an indication of our dedication to being the biggest online retailer in the world. There are distribution centers and warehouses across Europe and the USA.

Orders with more than 1 item are assigned processing times according to each item.

Prior to shipping before shipping, we'll conduct a thorough inspection of the items you have ordered. The majority of orders today are shipped in 48 hours. The expected delivery time will be between 3-7 days.

Returns

The stock is constantly changing and not fully managed by us due to the involvement of multiple parties including the factory and our warehouse. This means that the actual stock could fluctuate at any moment. It is possible that your order may be out of stock when the order is placed.

Our policy is valid for 30 days. Unfortunately, if 30 days have passed after you bought your item, we will not be able to provide a refund or exchange.

In order for your item to be eligible for return it must be in its original packaging, unopened and in the condition you received it. It should also be returned in its original packaging.

Related products

Hot Glue Sticks

Hot Glue Sticks

Methacrylate (MMA)

Hot Glue Sticks

Methacrylate (MMA)

Hot Glue Sticks

Hot Glue Sticks

PUR Hot Melt

Hot Glue Sticks

Spray Adhesives

Silicone

Hot Glue Sticks

Methacrylate (MMA)

Methacrylate (MMA)

Hot Glue Sticks

Methacrylate (MMA)

Spray Adhesives

Methacrylate (MMA)

Hot Glue Sticks

Methacrylate (MMA)

Spray Adhesives

Acrylic Adhesive

Methacrylate (MMA)

Hot Glue Sticks

Hot Glue Sticks